Selecting cabling and leveraging SCADA networks

In a previous article, we started looking at SCADA communication networks. We explored the differences between industrial and corporate networks, converged networks, core and edge switches along with redundancy and security considerations. In this article we continue the discussion, looking at the differences between fibre optic and copper communication cabling and how the network can be leveraged.

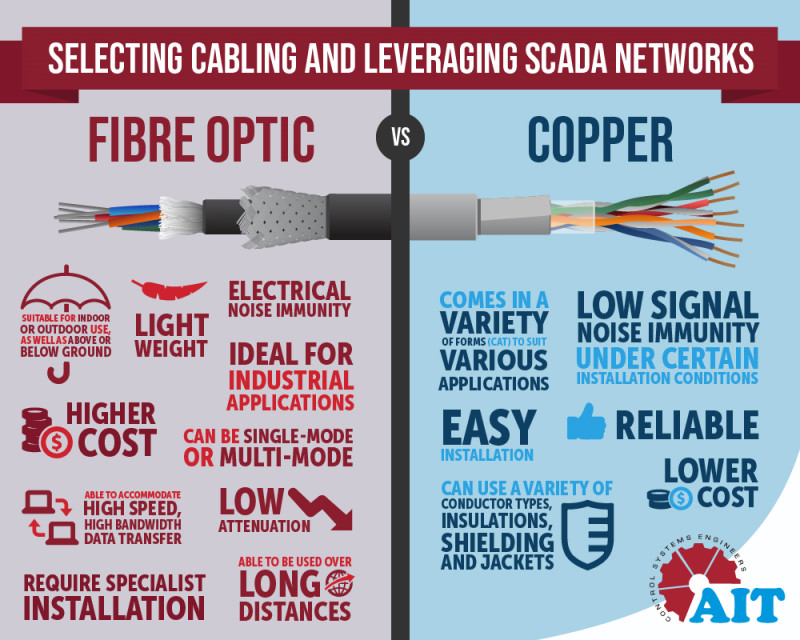

Fibre Optic vs copper cabling

Having the right type of cabling is crucial to reducing direct and indirect costs of a particular system failure. Fibre Optic (FO) and copper are the main types of cabling media used and they differ in two key aspects — the physical length of the network cabling segments and the rate of data transmission (bandwidth).

Fibre Optic cabling is ideal for industrial applications where high-speed, high-bandwidth data transfer is required. FO cabling typically has advantages over copper cabling including superior bandwidth (more data flow), low attenuation (low signal loss) and very high electrical noise immunity (optical signals are typically not affected by electrically generated magnetic fields), so more data can be transmitted without disruption. Compared to copper cabling, fibre is also lighter, safer and can be used over much longer distances (typically 10-40km however up to 100km are possible before repeaters are required).

FO cables are either single-mode (SM) or multi-mode (MM) and available for both indoor and outdoor use along with above and below ground options. SM FO cables are used where longer distances (>2km) between the data transmit and receive points are required, examples include telecommunications infrastructure, cable TV companies, universities and mine sites. MM FO cables allow more data to pass and are used in shorter distance applications (<1km) where signal immunity is paramount, such as in an industrial process or automation plant which has a typically noisy electrical environment.

Copper cabling has traditionally been used in industrial applications due to its low cost, ease of installation, reliability and low signal noise immunity (when using twisted pair/shielded cabling and segregated from power cables or other sources of electrical noise). FO cables are higher in cost than copper cables and also require specialist installation techniques including splicing/test equipment, so the trade-off between signal immunity and speed requires careful consideration.

Copper cabling comes in a variety of forms known as a Category, or CAT, examples include 5e, 6 and 6A twisted-pair cables, with the application requirements determining which form of cable would be best suited. CAT5a has been widely used for general data transfer requirements in the 10-100MB/s data transfer range; CAT6 is favoured for new installations to meet the increasing need for Gigabit data transfer rates; CAT6A can be used for futureproofing, minimising the lack of bandwidth and headroom. Copper cabling uses a variety of conductor types, insulations, shielding and jackets, including armored sheaths for harsh environments.

Accessing data from devices

Industrial process plants utilise a wide range of field devices to monitor and control systems, with the device data being transmitted via the communication backbone to the associated control station or main data centre. In many cases, the physical backbone is made up of a FO ring, or multiple rings for added redundancy capabilities, to ensure any attached devices are able to transmit their data continuously with no disruption in the event of a single point of failure to the network.

Most field devices or sensors are hardwired using a copper cable and don’t typically have the ability to connect directly to FO networks, they require some form of converter. For segregated individual devices this can be in the form of a standalone gateway, or for multiple devices in larger systems connected into network switches. As discussed in the previous article, network switches come in different hardware configurations and many can be specified with copper only ports, or a combination of copper and fixed FO ports or with SFP transceivers.

Another useful technology that has been developed is Power over Ethernet, or PoE. The PoE standard can be used to leverage an Ethernet network, it is designed to deliver low power over the same CAT5 or CAT6 copper cable that transmits data, so components such as CCTV cameras, sensors, field devices, wireless access points (WAP) or other low power devices can be connected to the network without having to install a separate power feed to each device. This can save considerable installation costs and also improve reliability as there are less points of failure to take into account.

There are two relevant standards for PoE: IEEE 802.3af for applications such as VoIP phone or WiFi access points, with a delivery rate up to 15.4W; and IEEE 802.3at PoE + which delivers up to 25.5W while remaining backward compatible with IEEE 802.3af.

The mix of cabling technology allows for robust designs to be implemented at relatively low cost when taking into consideration the total cost of ownership over the expected design life of the system. Having the ability to connect a wide range of devices to a site SCADA system ensures the plant owners and operators have clear visibility of the processes, including the ability to monitor individual communication and cable connections, and to take swift and appropriate action to resolve any issues before they cause a major disruption.

Leveraging off the network infrastructure via SCADA is a great way to improve system process efficiency, improve reporting capabilities, increase the process visibility, reduce plant downtime, reduce safety incidents and reduce overall operating costs.

In the final part of this article, we will look at environmental risks and their impact on reliability, as well as different vendors for networking products.