Reducing energy costs with Power Factor Correction

Large businesses and industrial operations consume large amounts of energy, making power one of the biggest costs for owners. On top of regular daily power charges, many network providers charge these businesses for the demand they place on the electricity grid. For owners and site managers looking to reduce power bills, this means it is now more important than ever to manage their site’s power consumption and importantly the Power Factor (PF). Here, we will look at the power and maintenance cost benefits of Power Factor Correction (PFC), improving load balancing and site Power Factor along with types of PFC.

What is Power Factor and PFC?

Power Factor is the ratio of active (real) power (kW) to total (apparent) power (kVA) of an AC system. Power Factor is expressed as a value between 0 and 1 and is either ‘leading’ or ‘lagging’ depending on the impedance of the system load. The total power (kVA) is the power available to the system and the active power is the power ‘consumed’ by the system loads. The loads are all of the devices and components that ‘consume’ electricity, including motors, transformers, lights etc.

In an ideal system, all the load devices and components are 100% efficient and the active power consumed is equal to the total power supplied so the Power Factor is 1, or at unity, this means there are no power losses in the system. In real world situations, all loads have some form of losses that contribute to a reduction in the efficiency of the system, so the power required to run the loads increases.

These losses are known as reactive losses which can be inductive (lagging PF), capacitive (leading PF) or (typically) a combination of both and are generally expressed as kVAR. The more reactive losses there are in a system, the poorer the Power Factor and more power is required to perform the same work.

If the Power Factor is high (i.e. close to 1), it indicates that power is being used efficiently, while a low Power Factor (<0.8) indicates that power use is inefficient with more current being drawn to get the same power output, and therefore more power is being consumed than is being used usefully. If the Power Factor is low, it is possible to improve the system efficiency by installing a Power Factor Correction (PFC) unit or active harmonic filtering.

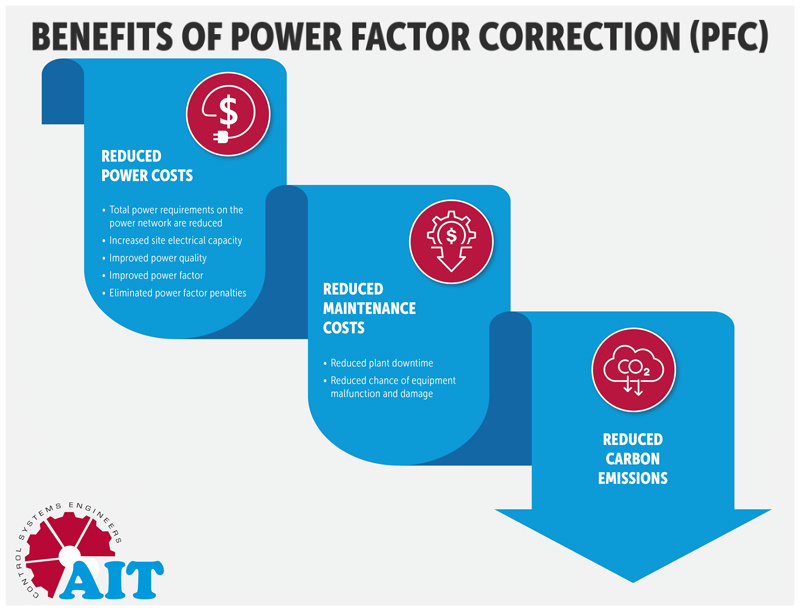

The benefits of Power Factor Correction

There are two major benefits of PFC for both large businesses and industrial operations: reduced power costs and reduced maintenance costs.

PFC helps reduce the total power requirements on the power network and increases site electrical capacity, the direct result of improving Power Factor is to reduce electricity costs. The other major benefits of installing a PFC is to improve power quality, reduce plant downtime and to lower maintenance costs.

The supply of reliable, consistent and quality power is critical for large businesses and industrial operations. Poor power quality due to disturbances such as interruptions, voltage dips or harmonic pollution is one of the major causes of downtime, equipment malfunction and damage, all of which are costly to manage.

With a significant percentage of these disturbances the result of equipment installed at the facility, PFC helps improve a facility’s Power Factor and maintain power quality by stabilising electrical networks and load balancing when disturbances occur.

Types of PFC units

PFC units can be installed at a building or facility to improve power quality, adding in PFC ensures the site is using power more efficiently which reduces demand charges. One of the most common, practical and economic ways to improve Power Factor is to install passive PFC such as adding a capacitor bank to the site’s distribution system.

Adding capacitors of the correct size to the power system produces leading reactive power that offsets, or balances, the lagging reactive power and reduces the overall site power requirements. There are two ways this can be achieved: individual load compensation and centralised compensation.

Individual load compensation applies to motors, transformers and more generally to loads with a high time of operation. Capacitors are connected in parallel to the terminals of the loads, this reduces the power requirements of specific equipment. For new installations, this means smaller switchgear and power cables can be installed thereby reducing capital expenditure. For existing installations, adding individual load compensation improves specific sections of plant and helps to reduce the overall power costs.

Centralised compensation uses automatically switched capacitor banks at the feeder or substation to provide PFC and reduce low Power Factor penalties. By automatically adjusting capacitance in the system, the exact amount of PFC is provided for the entire site, eliminating over-capacitance and overvoltage. It typically has a lower cost per kVAR correction than individual load compensation.

In the next part of this article, we will continue to look at how to achieve PFC with active harmonic filtering and electronic VAR control, installation considerations of PFC equipment, ongoing costs and energy auditing services.